Table of Contents:

- What is 3D Scanning?

- What is BIM?

- The Scan-to-BIM Process

- The Benefits of Laser Scanning and BIM Integrations

- Questions to Ask When Integrating Laser Scanning to BIM

BIM (Building information modeling) has revolutionized the construction industry, offering a highly efficient way to manage projects and prevent errors across all build stages. 3D scanning complements the process with one of the fastest and most accurate methods for collecting data about a job site or building.

By integrating these two technologies, you can create a scan-to-BIM process that helps you work more efficiently, improve project outcomes and maximize your return on investment.

What Is 3D Scanning?

3D scanning uses time of flight LiDAR (light detection and ranging) technology to collect data points from a scanner's physical surroundings. They can capture information about the relative location and shape of structures and sometimes other characteristics, like reflectivity and color.

These data points come together in a point cloud, which modeling software can use to create 3D representations. While 3D BIM creation is one common use for scanning data, you'll also find it in traditional 2D CAD (computer-aided design) workflows as well.

3D scanning is well-suited to collect data used for BIM/CAD because it combines speed and accuracy. These qualities are hard to achieve with other methods like photogrammetry, which requires a technically skilled photographer and offers lower levels of detail. Facilitating fast BIM has made 3D laser scanning a powerful force in construction.

What Is BIM?

BIM refers to an information-loaded digital 3D model of a building that engineers, architects, contractors and other professionals can use throughout a construction project. When paired properly with 3D scanning, you can even create a highly accurate digital twin at the end of the project for use in the entire building’s lifecycle.

While visualization is a major component of BIM, it also incorporates other types of information, like plans for materials and mechanical, electrical and plumbing resources. The result is a highly valuable, collaborative space for teams to share information and take action. In construction, BIM is used with new and existing builds for planning, quality assurance, progress monitoring, building management and many other tasks.

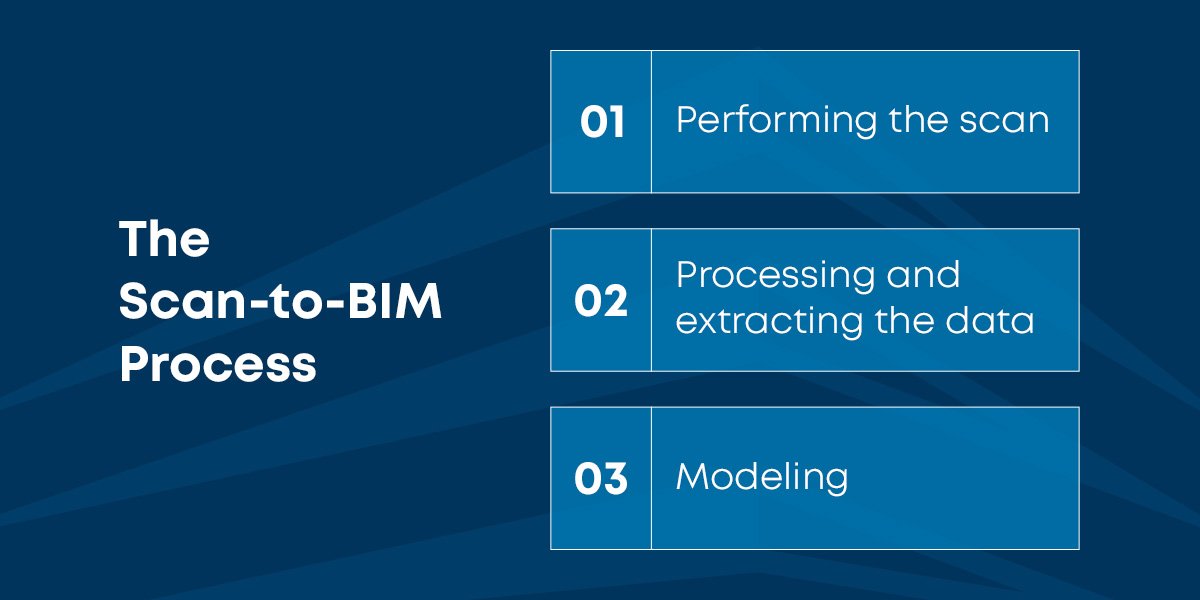

The Scan-to-BIM Process

Traditionally, construction teams used manually collected data from tape measurers to build BIM models. As you can imagine, this was a slow and error-prone process. 3D scanners dramatically speed up data collection and achieve extreme detail with precision and accuracy, making BIM much more valuable and practical. Getting from a scan to a functioning 3D model still takes several steps, encompassed in the scan-to-BIM process:

- Performing the scan: The scan-to-BIM process starts with using a 3D scanner to collect data points from the environment. As the scanner detects nearby structures, it plots data points along edges and surfaces, recreating what is called a point cloud.

- Processing and extracting the data: Next, the point cloud moves to processing software that parses down unwanted elements, making it more manageable for use inside 3D model authoring software.

- Modeling: In the BIM software, your processed point cloud becomes a 3D model. You can also add relevant data at this stage, such as specifications, and run quality checks to validate the model's accuracy.

From here, you can use your BIM model to perform other tasks like quantity takeoffs, clash detection and facility management. You might also use it to generate deliverables, such as photo-realistic images or reports.

The process can take anywhere from a few days to a few weeks, depending on the complexity and size of the building. Individual scans typically take under 5 minutes and are non-intrusive, so you can often perform them without shutting down facilities or putting team members in hazardous areas.

The Benefits of Laser Scanning and BIM Integrations

BIM and 3D laser scanning integrations build off each other to provide a wide range of benefits for construction teams.

1. Error Reduction

By comparing building models with as-built structures, you can identify problems before they become more costly and time-consuming to fix. The high precision of LiDAR technology also supports increased accuracy in your data. 3D modeling is an excellent tool for ongoing quality assurance.

2. Improved Collaboration

BIM can help all stakeholders and teams stay on the same page with clear visualization and centralized communication space. Collaboration is central to BIM standards, bringing professionals together for faster decision-making and better data visibility.

Many BIM platforms also offer extensive integrations with business systems to minimize manual data entry. Integrating laser scanning to BIM helps ensure the integrity and fidelity of the data during these discussions.

3. Streamlined Workflows and Efficient Processes

3D scanning is highly efficient, allowing your team to maximize productivity during data collection and modeling. With an accurate model, you can also improve predictions for more optimized processes, from site layout to material purchasing.

4. Reduced Costs

You can reduce project operating costs by avoiding reworks and boosting efficiency. 3D scanning supports earlier error detection — which prevents problems from becoming more expensive — through improved accuracy. It also provides access to areas that may be difficult to measure manually and provides more detailed planning to keep you from going over budget.

5. Added Value

Similarly, point clouds and models allow you to offer value-added services like documentation for future facility management or renovations. You can also use it for products such as virtual walkthroughs for stakeholders. With these additions, you can increase customer satisfaction and the value of your services.

6. Easier Remote Work Management and Progress Tracking

Remote teams are increasingly common, and regular 3D scans allow you to keep your model updated, providing an accurate representation of project status. Since scans are so quick, they don't interrupt your workflow. Any stakeholders not on-site can easily join in on discussions and monitor progress.

Questions to Ask When Integrating Laser Scanning to BIM

Preparing for the switch can ensure a smooth and predictable process for any business implementing 3D laser scanning and BIM. Before buying your solution, explore elements like:

- How well it fits into your workflow: What systems do you already use? Can you use the data within your existing BIM workflow? Strong integrations can help streamline your workflow and boost the system's value. Consider your existing workflow on-site, too, and determine where your scanning might fit.

- Your technical expertise: 3D scanning comes with a slight learning curve, so you may need to train some employees and create a scanning team. Find a skilled training partner who can educate your team effectively and help you get the most out of the system.

- Your business goals: Consider how a 3D scanning and BIM system supports your plans, such as improving or bolstering client satisfaction.

Choosing the right hardware and software is vital for maximizing the value of 3D scanning and BIM, so analyze your needs carefully before you buy.

Transform Your Workflow With 3D Scanning and BIM

Construction businesses of all sizes can reap the benefits of laser scanning and BIM to work more efficiently and cost-effectively. At BuildingPoint SouthEast, we bring trusted technologies and support to construction sites across the Lower East Coast.

With leading Trimble 3D scanners and software, you can confidently implement this powerful technology into your workflow. Test a scanner with our rental options, and lean on our skilled technicians for repairs, support and calibration. However you plan to integrate 3D laser scanning and BIM, we're here to help.

Reach out today to explore this powerful technology with our team or request a quote.